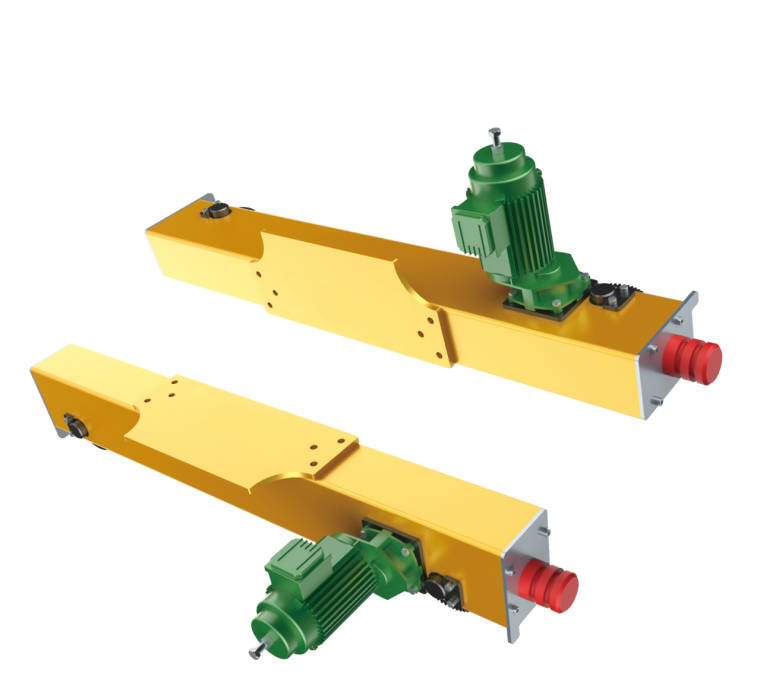

1.Open pinion type end carriage

Open pinion type end carriage refers to a design in which the transmission gears (primarily large gears) are completely exposed to the outside environment, without the protection of an enclosed gearbox.

Structure and Operating Principle:

● End beam body: as a supporting structure, with wheels mounted at both ends.

● Geared-motor: install on the body of end beam.

● Gear : A small gear is mounted on the output shaft of the reducer, directly meshing with a large gear fixed to the wheel axle. This pair of gears is not covered by any housing and is “open.”

Features:

● Simple structure, low manufacturing and maintenance costs: The gearbox is eliminated, resulting in a small number of parts.

● Good heat dissipation: The gears are directly exposed to the air, making heat dissipation easier.

● Easy inspection: The meshing condition, wear, and lubrication status of the gears can be visually inspected.

Applicable scenarios:

Primarily used in applications with low hygiene requirements, low-level (infrequent) work, slow speeds, and strict cost control, such as older, lightweight, or workshop-based cranes.

2. Hollow Shaft type end carriage

Structure and operating principle:

● body: Also a supporting structure.

“Geared motor: Modern cranes often use a “three-in-one” drive unit that integrates a motor, brake, and reducer.

● Enclosed gearbox: The entire drive system (angular bearings, wheel axles, large and small gears) is sealed in a gearbox filled with lubricating oil. The output shaft of the drive unit (such as Geared motor) directly drives the wheel axle through a coupling.

Features:

● Advantages:

● Excellent lubrication and low wear: Gears and bearings are splash lubricated in an oil sump or use forced lubrication, providing sufficient and reliable lubrication and long service life.

● Excellent sealing and anti-contamination: Effectively prevents the ingress of external impurities, suitable for harsh environments (such as dusty, humid workshops, and outdoor environments).

● Smooth operation and low noise: The gearbox acts as a soundproofing and buffer.

● High safety: All moving parts are enclosed, eliminating the risk of entrapment.

● Long maintenance-free intervals: Only regular inspection or replacement of the gear oil is required, with no frequent relubrication of grease required.

Applicable Applications:

This is the most mainstream and standard configuration for modern bridge and gantry cranes. It is suitable for all medium- and heavy-duty industrial applications with high workloads (busy workloads), harsh environments, and requirements for long equipment life and easy maintenance.

Post time: Oct-10-2025