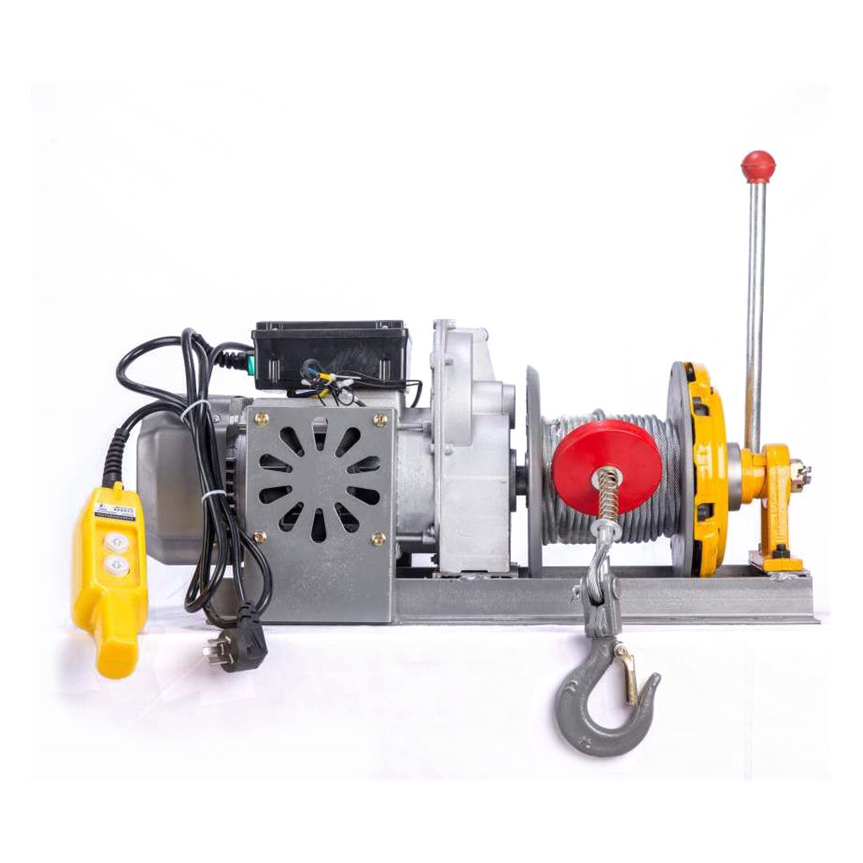

JM electric wire rope winch

Product Informations

JM electric wire rope winch is powered by an electric motor, is driven by an elastic coupling, a three-stage closed gear reducer, a jaw coupling, and a hydraulic push rod brake. JM electric wire rope winch has a large lifting capacity and is widely used in construction. It can also be used as supporting equipment for modern electronic control automatic operation lines for material lifting or flat dragging in water conservancy projects, forestry, mines, docks, etc.

JM winch operating instructions

1. The wire ropes on the reel should be arranged neatly. If they are overlapped or slanted, they should be stopped and rearranged. It is strictly forbidden to pull and step on the wire rope with hands or feet during rotation. The hoist wire rope is not allowed to be fully released, and at least three turns should be retained.

2. The wire rope is not allowed to be knotted or twisted. If the wire is broken more than 10% within a pitch, it should be replaced.

3. During the operation, no one is allowed to cross the wire rope, and the operator is not allowed to leave the hoist after the object is lifted. Objects or cages should be lowered to the ground during rest.

4. During the operation, the driver and signalman should maintain good visibility with the hoisted object. The driver and signalman should cooperate closely and obey the unified command of the signal.

5. In case of a power outage during operation, the power supply should be cut off and the lift should be lowered to the ground.

6. Obey the signal of the commander during the work. If the signal is unknown or may cause an accident, the operation should be suspended, and the operation can be continued after the situation is clarified.

7. If there is a sudden power failure during operation, the knife should be opened immediately and the transported objects should be put down.

8. After the operation is completed, the material tray should be dropped to the ground and the electric box should be closed and locked.

9. The steel wire rope is worn and mechanically damaged during use. Spontaneous combustion corrosion and local damage are inevitable. Protective oil should be painted at intervals.

10. Overload use is strictly prohibited. That is, the maximum carrying tonnage is exceeded.

11. Do not directly hoist high-temperature objects, and protect the objects with edges and corners.

JM Electric Winch

|

Model |

JM1T |

JM2T |

JM3T |

JM5T |

JM10T |

|

|

Line pull capacity (kg) |

1000 |

2000 |

3000 |

5000 |

1000 |

|

|

Wire rope average speed (m/min) |

16 |

16 |

10 |

10 |

10 |

|

|

Wire rope Dia.( mm): |

9.3 |

13 |

15 |

21.5 |

30 |

|

|

Reduction box |

Type |

ZQ250 |

ZQ350 |

ZQS470 |

ZQS670 |

ZQS790 |

|

Transmission ratio |

48.57 |

48.57 |

75 |

139 |

175 |

|

|

Drum (mm) |

Diameter |

140 |

200 |

220 |

377 |

500 |

|

Length |

350 |

500 |

530 |

650 |

800 |

|

|

Capacity for wire rope (m) |

100 |

150 |

150 |

250 |

250 |

|

|

Motor |

Type |

YE2-112M-6 |

YE2-160M-6 |

YE2-160M-6 |

YE2-160L-6 |

YE2-200L-6 |

|

Power(kW) |

2.2 |

7.5 |

7.5 |

11 |

22 |

|

|

Rotating speed (r/min) |

1000 |

1000 |

1000 |

1000 |

1000 |

|

|

Hydraulic brake |

YWZ-100/18 |

YWZ-200/25 |

YWZ-200/25 |

YWZ-300/45 |

YWZ-300/90 |

|

|

Dimension (cm) |

700*600*420 |

1000*600*570 |

1020*900*600 |

1240*1230*800 |

1500*1450*1020 |

|

|

Weight (kg) |

180 |

380 |

550 |

1000 |

1700 |

|